Major Northeast Power Plant

Client

Major Northeast Power Plant

Location: Major Northeast Power Plant

Components: Packing Box / Shaft Sleeve / Packing / Enclosed Shafting

The Problem

Excessive leakage due to shaft sleeve wear, incorrect packing, and lack of maintenance. The plant is experiencing the high cost usage of city water to lubricate the pump bearings.

Published by Rockwell International, Flow Control Division, a continuous stream of water through a ¼” diameter hole at 60 psi will use 1,181,500 gallons of water in a three month period.

Our Solution

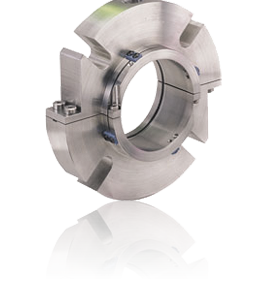

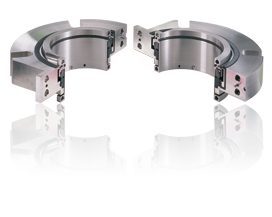

Replace the antiquated sealing system with a FLEX-A-SEAL SPLIT CARTRIDGE MECHANICAL SEAL. The FLEX-A-SEAL Style 85 is the world’s only patented split cartridge seal.

- The Style 85 can easily convert a packed pump to a sealed pump. Once installed, it does not require continual maintenance attention.

- The Style 85 is the only split seal that is factory pressure tested to insure its integrity when shipped to the field for installation.

- The Style 85 has only two halves to be handled by the installer. No more handling lapped faces, loose parts, o-rings and associated hardware. Simply attach two halves over the shaft and mount to the pump like any other cartridge seal.

- Standard sizes for the Style 85 range from 1.687” – 8.500” shaft diameters.

Results

Reduction in pump maintenance and city water cost to operate the unit. Elimination of winter ice sculptures and hazardous work conditions.

Metro Pumps & Systems Inc. is a leader in the Northeast for solving the toughest repair problems in your plant.